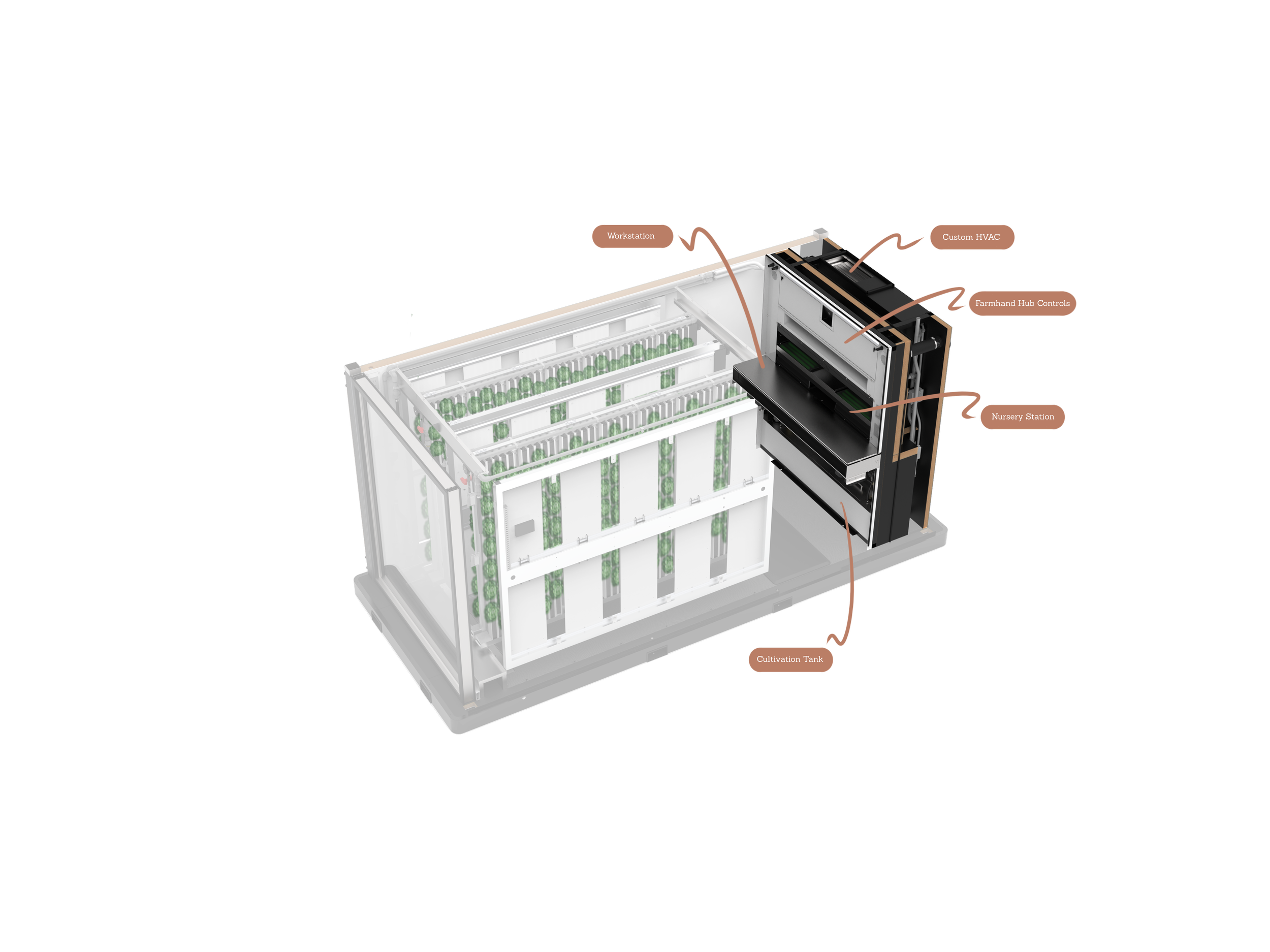

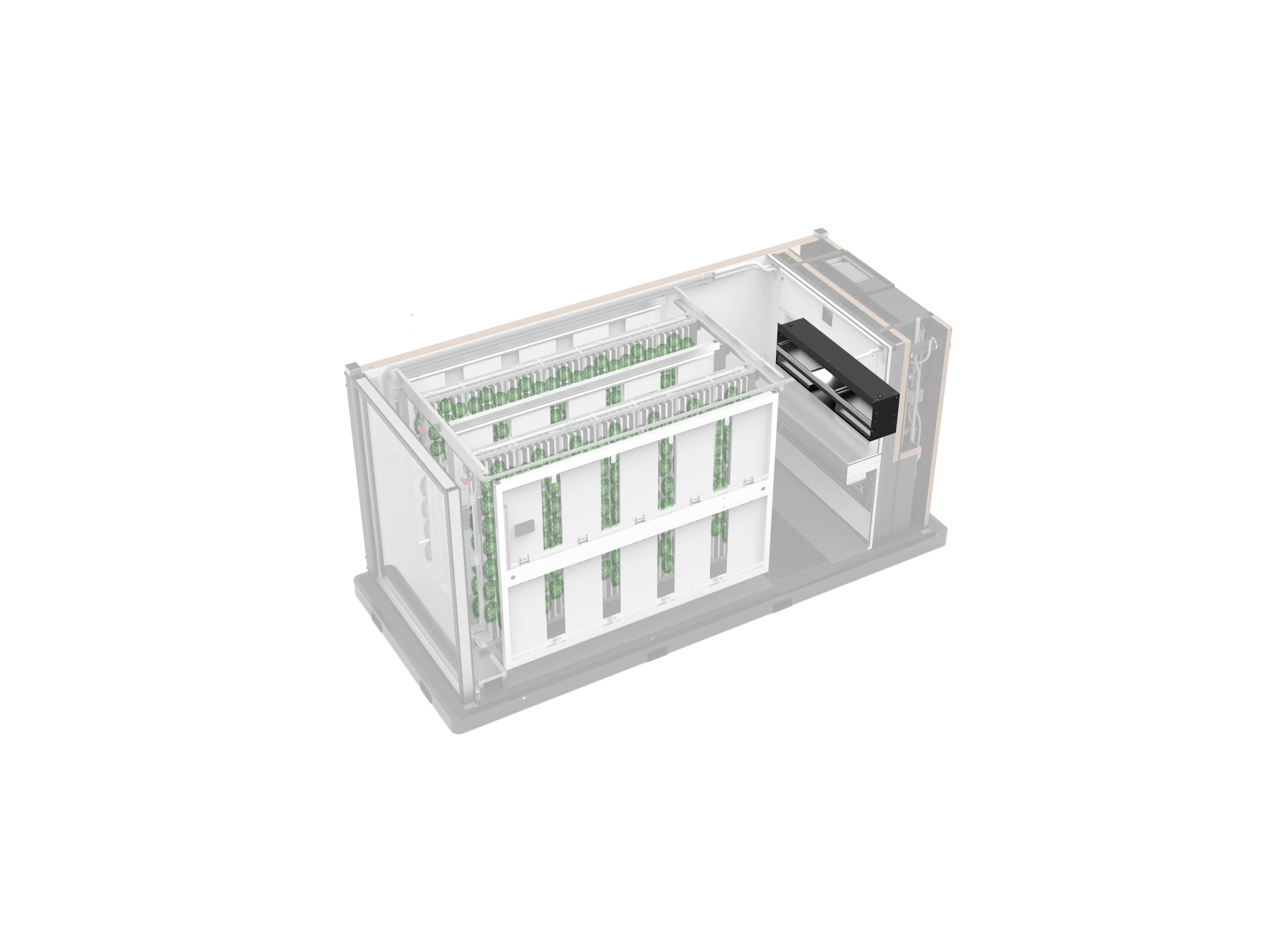

Farmhand modules, unit hookups, atmosphere control, water control and workflow center. The Life Support Module is what keeps this Garden growing.

Putting the plants on Life Support

Workstation

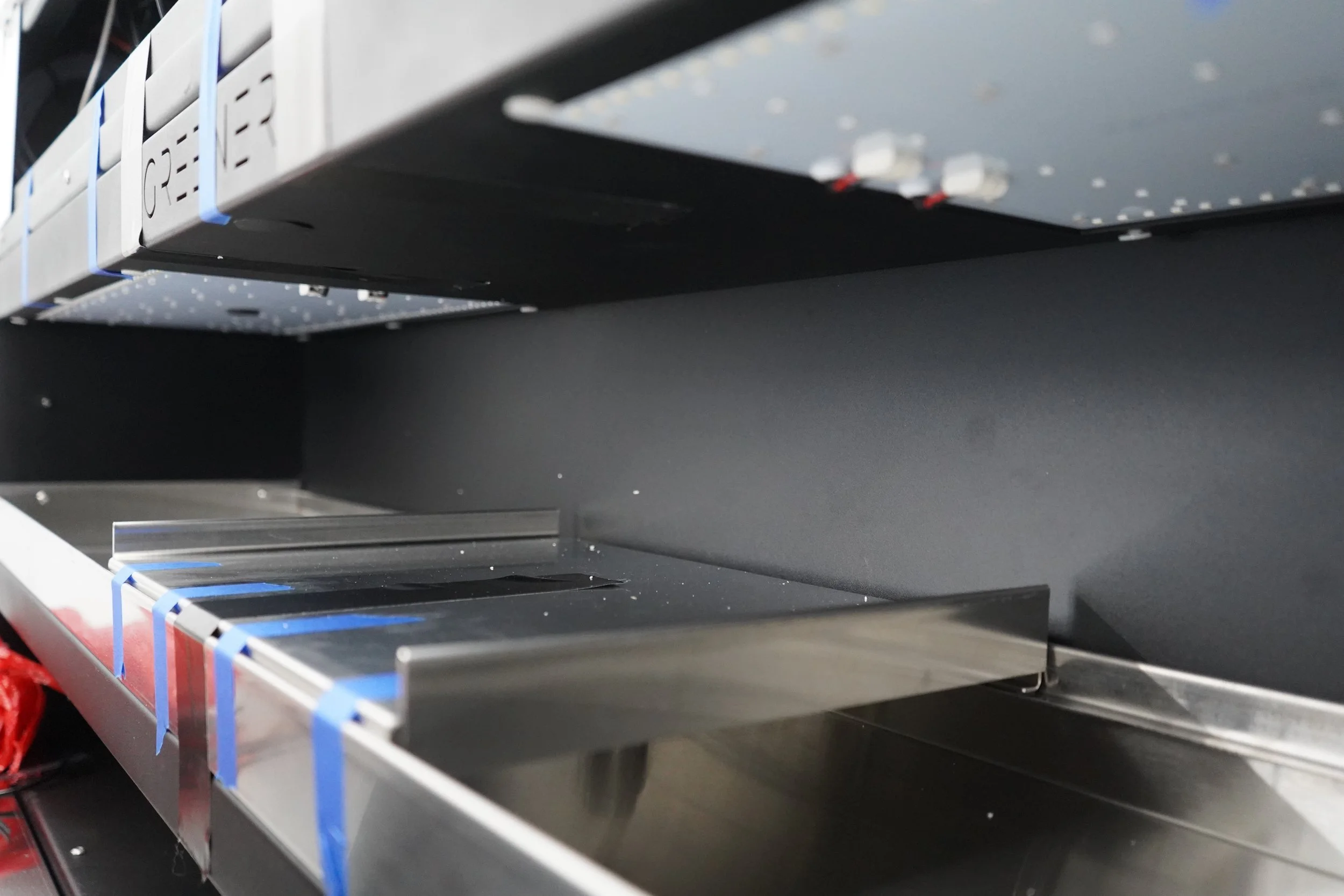

Stainless steel worksurface with integrated storage

Nursery Station

Seeds get the perfect start with a dedicated germination shelf, ebb and flow trough, full spectrum LEDs and 1080p cameras to monitor them to transplant

Nutrient Delivery

Liquid Nutrients precisely dispensed maintain the perfect water conditions to expedite growth

HVAC

High quality parts in a totally re engineered package provides 1.25 tons of cooling, 1/2 gph of dehumidifying and electric reheat to provide the perfect environment in any environment

The Heart of the Garden

A nursery for seed germination and propagation is incorporated into a workstation used for seeding, transplanting, and harvesting. The nutrient delivery system houses tanks that dispense precise volumes of liquid nutrients into a 50-gallon tank, mixing with water to create the perfect nutrient solution for the plants. A custom HVAC unit cools, heats, and dehumidifies the air with 1,000 CFM of air movement.

-

1080p high definition camera gives a full picture of the Garden

-

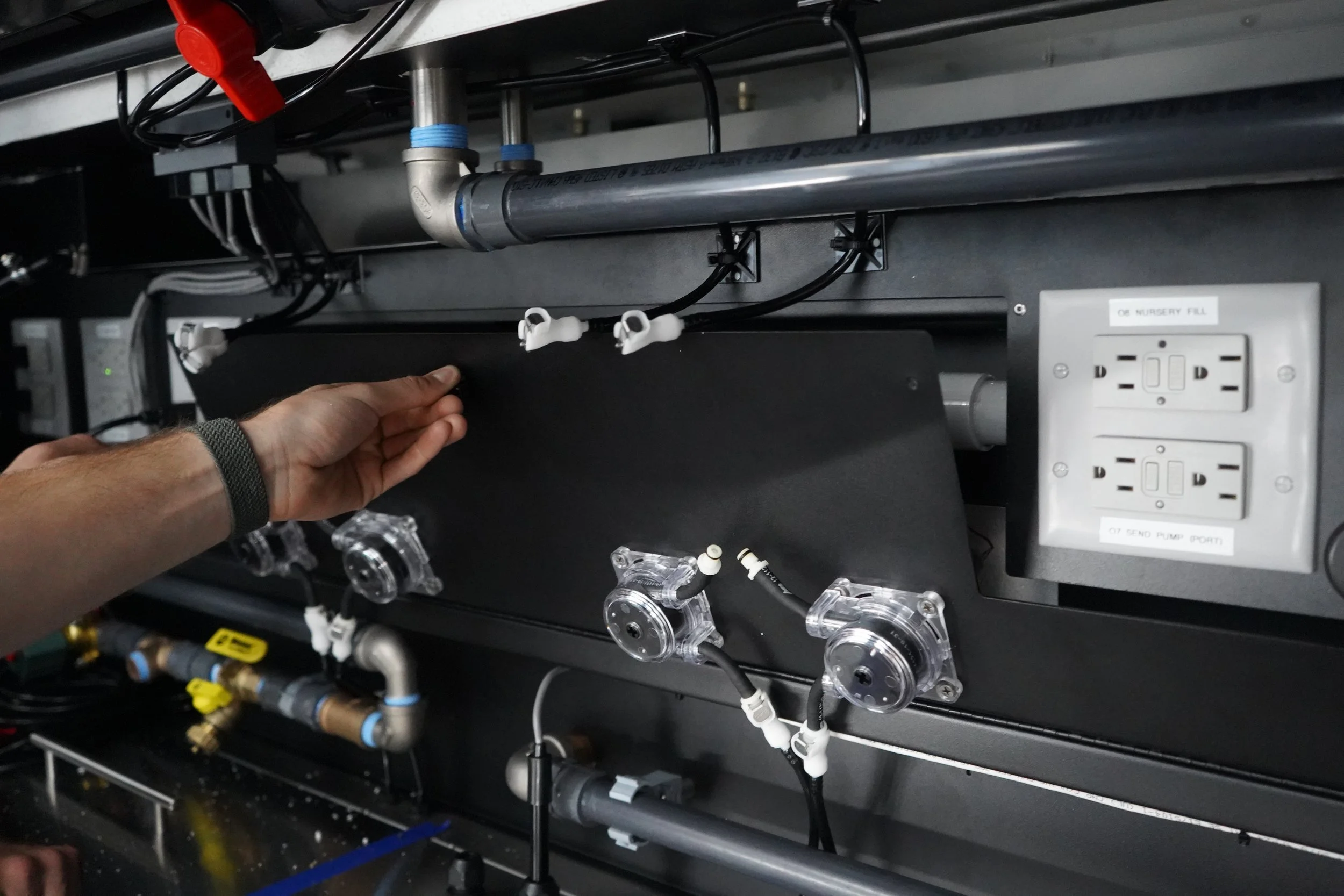

Each of the Farmhand hub modules and control systems are easily accessible behind a drop down panel

-

Germination and seedling propagation starts the plants off on the right foot

-

Dark to start then white with light, the germination shelf allows for a simple way to sprout your seeds

-

A dedicated space for harvesting, transplanting and seeding

-

Peristaltic pumps delivery nutrients to the cultivation tank with extreme precision

-

This reservoir automatically fills, recirculates water past the hydro sensor, is mixed with nutrients before the send pumps deliver it to the plants

Find your Station

Minimalist design, maximum efficiency

The Workstation

-

Food safe work surface makes clean up a breeze

-

Pop the hood to easily access nutrient delivery tanks and additional storage

-

Nutrient Tanks house a collection of liquid nutrients and pH manipulators that dispense into the cultivation tank

-

Everything Has a Place

The workstation acts as the command center of the Garden™. With integrated shelving and a stainless steel worktop, seedlings are propagated right where you need them for transplanting. All farm control modules are accessible behind an access panel, and a 1080p camera provides a perfect view of your plants.

-

Access Hidden in Plain View

Tucked away until needed, the Garden™ offers easy access to every necessary touch point. Control modules are serviced behind a hinged access panel. The nutrient tanks slide inside the table to maximize volume and usability. Easily detached with a quick-connect fitting, the tanks are fully removable for filling and cleaning.

Nursing your obsession with "fresh"

Where seeds lay their roots

The Nursery

-

Remote monitoring of every single seedling gives you confidence your Garden is healthy while giving you insight into when they are ready for transplant

-

Red, blue and white light shower the seedlings with the perfect intensity of photosynthetic light

-

Drop your seeds into our peet moss plugs, moisten them with a few sprays and pop on the humidity dome. When the seeds pop out they are ready to move to the Seedling Trough

-

An ebb and flow trough irrigates your seedlings automatically and periodically. An adjustable overflow drain allows you to control the water level to accommodate multiple tray types for seedlings, microgreens, clones and more

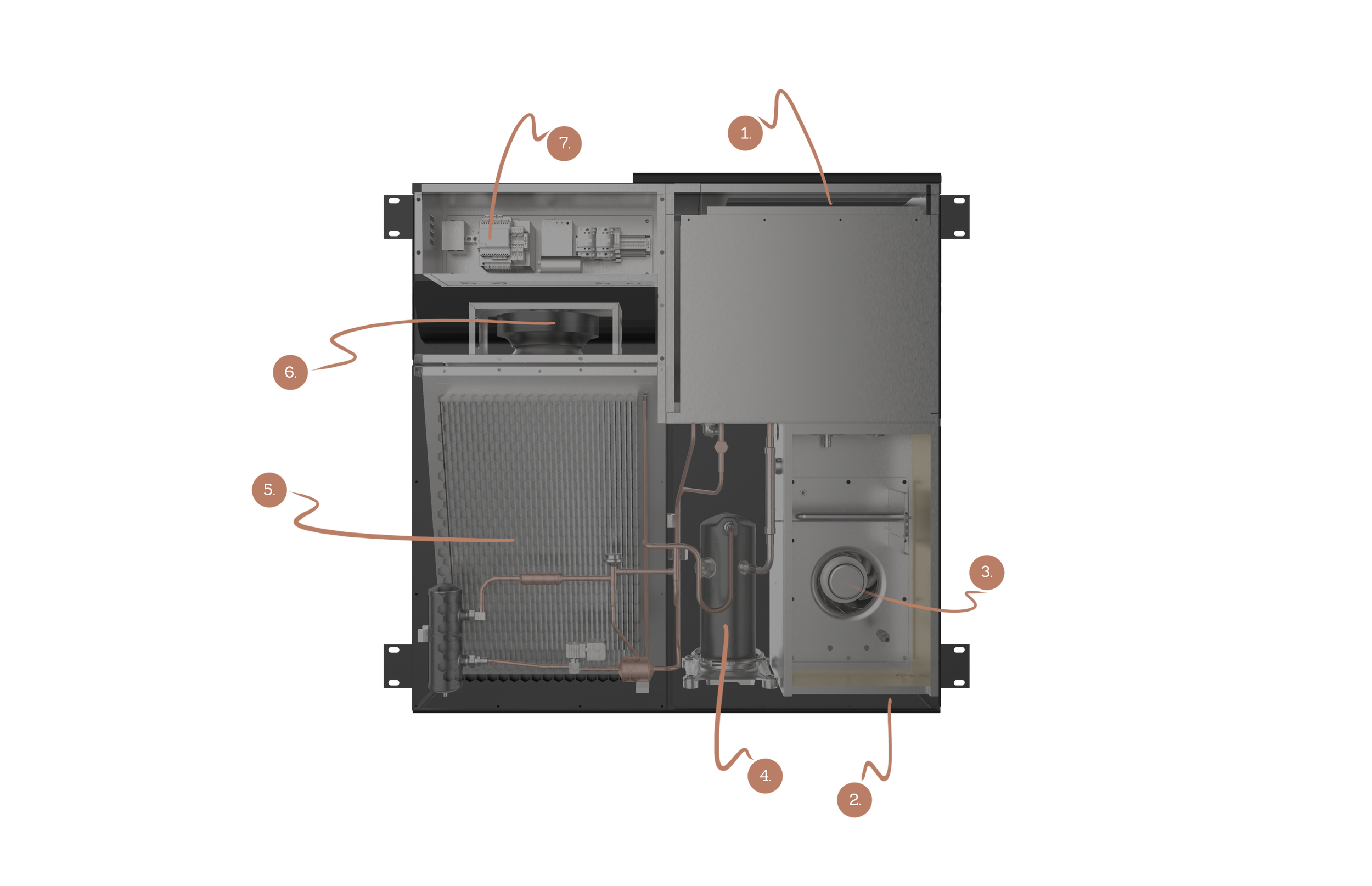

Designed for Manufacturability and Accessibility Heating

Each sub system is designed to be easily accessible and replaceable making assembly and servicing a breeze

Nutrients on Demand

Custom nutrient blends delivered with precision

-

Farmhand "Form" is the first part of our line of proven nutrients

-

"Grow" the second part of the Farmhand nutrient mix is comprised of

-

Acidic Liquid is dispensed into the Cultivation Tank. Maintaining the proper pH is imperative to allowing the plants to efficiently absorb nutrients

-

An alkaline liquid is used to raise the pH. Most farms with treated water do not require pH up as the nutrients are fairly basic and often raise the pH of their own. In that case an additional nutrient solution can be used instead to hone in even more precisely on the water conditions

Custom HVAC

Cooling

Dehumidifying

Heating

-

A standard 20" x 10" x 1" filter is used to filter particulate from the air. This filter is inexpensive and easily replaced

-

The air supply location is located on the bottom of the unit

-

A centrifugal fan produces over 500 CFM into the growing area

-

Cooling capacity of 14000 (BTU/hr)

-

Effectively removing the heat from the farm

-

Less than 65 dB, the condenser fan helps bring the coolant back to liquid form with a whisper

-

All connections are accessible in the centralized electrical enclosure. Making servicing a breeze

-

Cooling

Hot humid air is pulled from the top of the unit, through the filter and evaporator coils and back into the grow area. Condensate is captured and returned into the cultivation tank

-

Heating

Cool air is pulled through the top of the unit and run past the electric reheat coil, warming it and returning it to the grow area

The air in the Garden™ is cycled through the shell to the HVAC unit and back to the grow area, being cooled or heated to provide the perfect temperature and humidity for the plants.

Take a minute to write an introduction that is short, sweet, and to the point.