The future is green, with a splash of pink

By flipping the field on it’s end we harnessed the power of gravity

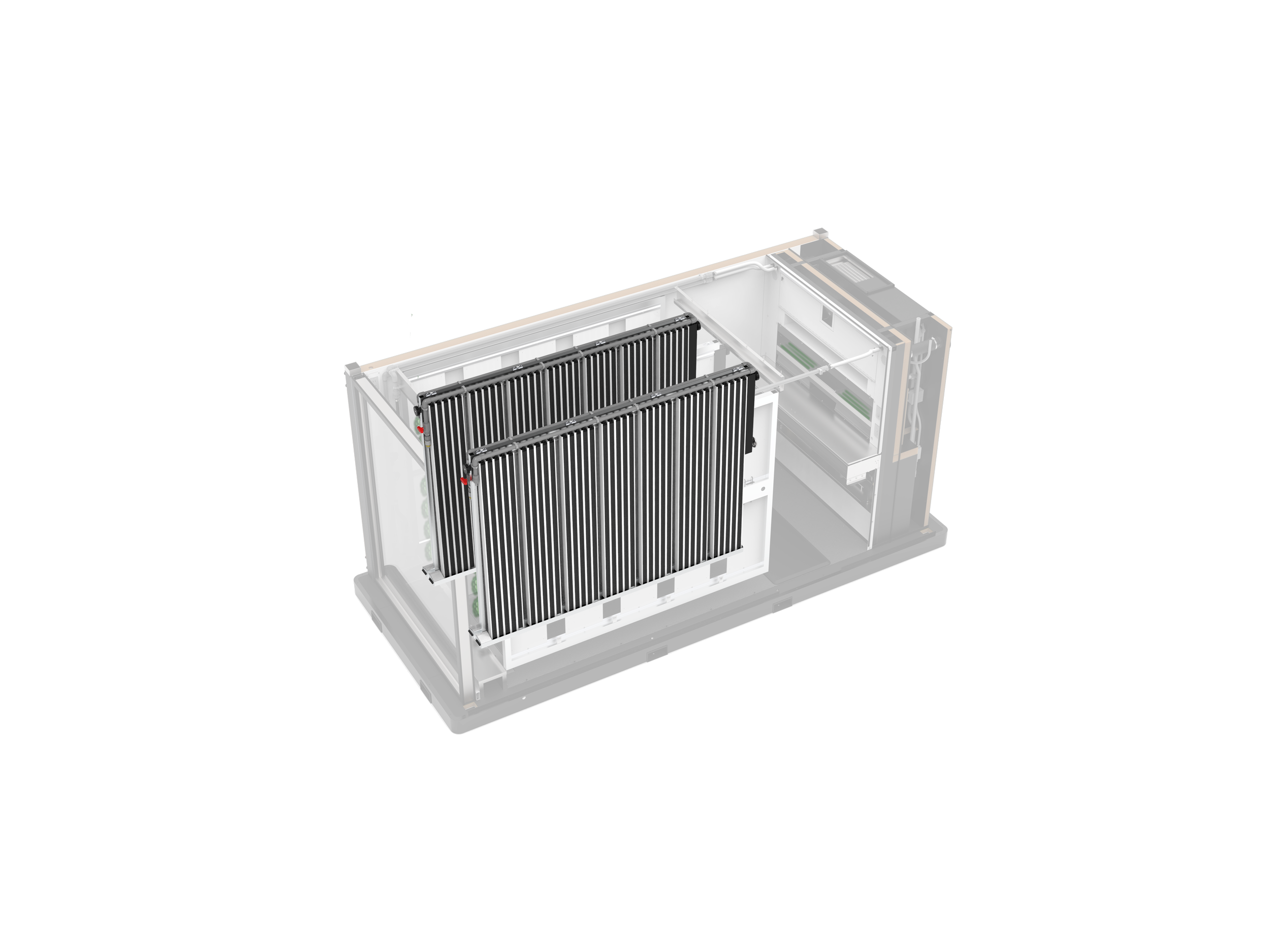

A Production Powerhouse

The Cultivation Area

Grow Rows

A five channel growing apparatus optimized for high density crop production, user convenience and versatility

LEDs

Custom high efficiency LED boards are equipped with red (660nm) and blue (440 nm) and infinite dynamic lighting modes to produce the exact μmol/m²/s for the crop. Simply put we made the sun controllable

Vertical Drip Irrigation

Pressure regulated emitters direct 2 gallons per hour of nutrient rich water solution directly to the roots of the plants. The water is constantly monitored, replenished with nutrients and recycled back to the crops. The only water consumption is from what the plants absorb

Track System

An overhead track system allows the walls of crops and LED’s to be moved laterally in the farm to create aisles where needed to access any crop

Inch by inch, row by row, how the Garden grows

An adaptive planting apparatus, illuminated by dynamic LED lighting and nourished with the perfect nutrient and water mixture, creates the ideal conditions every day for 10,000 linear inches of growing space. Each inch is accessible via an integrated overhead track system

This Panel Discussion is Over, Lets Grow.

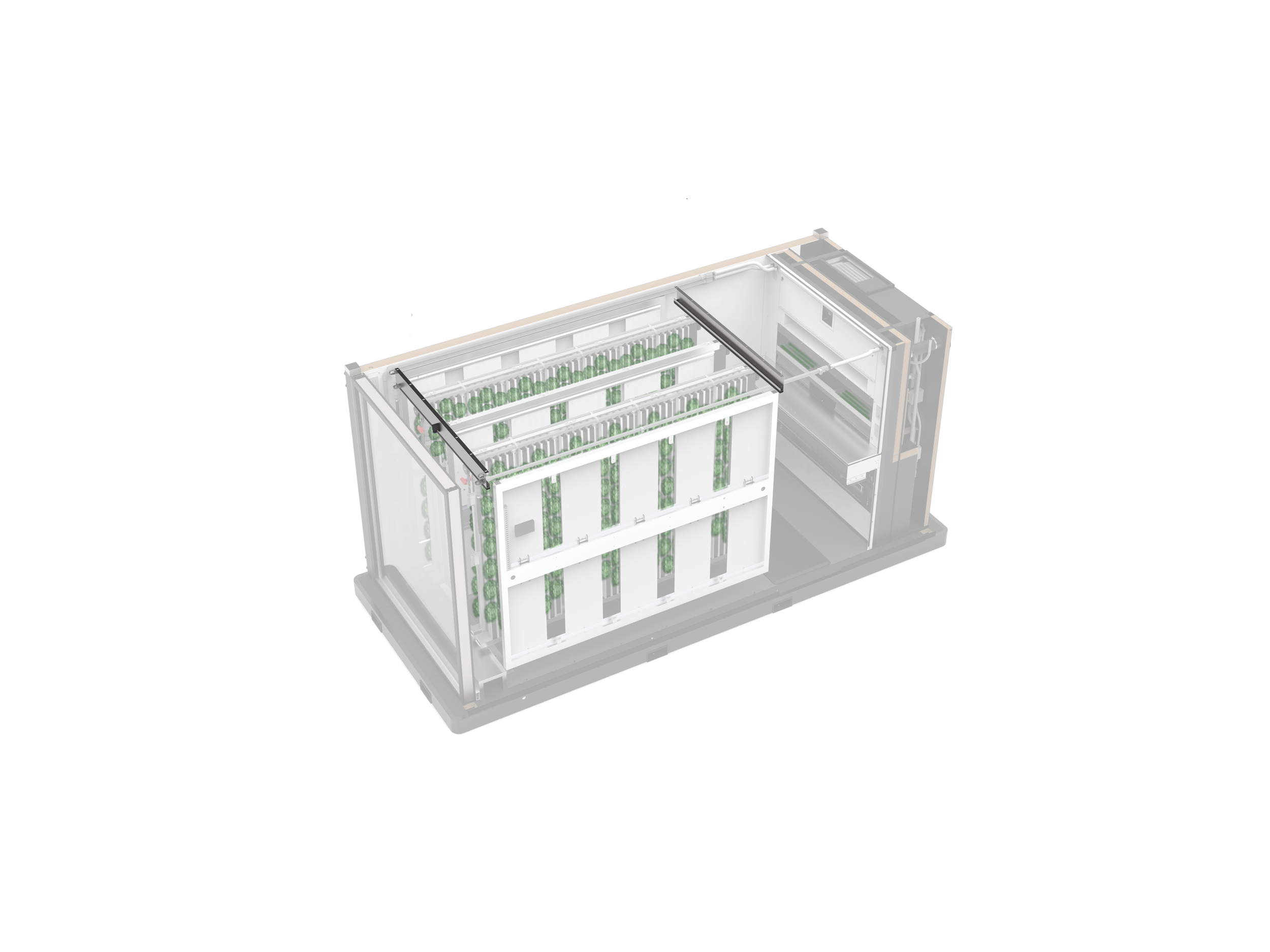

The Grow Rows

-

28 of our custom Plant Panels create the vertical plot in the Garden. Five channels of growing space per panel and open faced design make for an adaptive panel that is easy to work with.

-

Nutrient enriched water is fed into the plant panels to send water directly to the roots of the crops before draining back to the reservoir to be cycled back to the plants

-

The Grow Rows utilizes gravity to feed water to the plants and back to the reservoir.

-

Rack gear belt housing encloses the mechanisms used to move the wall laterally in the Garden

Many ways to Grow

5 channels of vertical, adaptive and customizable growing space

-

28 Plant Panels in the Garden create nearly 10,000 inches of growing space

-

5 growing channels per panel creates a system capable of growing a huge variety of plants in multiple arrangements

-

2 gallons per hour of nutrient enriched water are delivered to each channel, using gravity to efficiently and precisely provide water to each of the over 2,800 plants

-

Stagger Planting

Using channels 1,3 and 5 stagger planting is meant for plants with specific spacing needs. Channels 2 and 4 are intentionally left empty to provide space for the plants to expand into

-

Inter Planting

Like stagger, interplanting uses channels 1, 3 and 5 to plant a hearty green. But also utilizes channels 2 and 4 to plant a root crop. The root crop is harvested just as the space is occupied by the hearty green

-

Linear Planting

Linear Planting using the full length of all 5 growing channels to plant high density crops such as herbs and lettuce mixes

Minimalist Design, Maximum Yields

-

Pressure regulated emitters deliver 2 gph of water to each of the 5 growing channels

-

A funnel directs the water to the "Dripstix". A funnel directs the water to the "Dripstix" which carries the water down the length of the Plant Panel which carries the water down the length of the Plant Panel

-

The plants are held in place with an engineered reticulated foam

-

Everything is housed in a rigid high impact polystyrene panel

-

Double keyholes create and quick and secure mounting point for each of the 28 plant panels

-

Grooves built into the panel guide the panel into its hanging position

Track System

Maximizes space and provides access each of the 28 plant panels

Rack Driven Track System

-

Home Position

The Cultivation walls are spaced evenly in "Home" position to maximize plant space, create a uniform lighting environment and ensure adequate airflow

-

Harvest/Transplant Position

A rack and pinion system ensure the rows stay parallel while also allowing the user access to all of their crops and components

Move with a Turn | Tighten in a Twist | Access Easily

You Can Feel The Tension

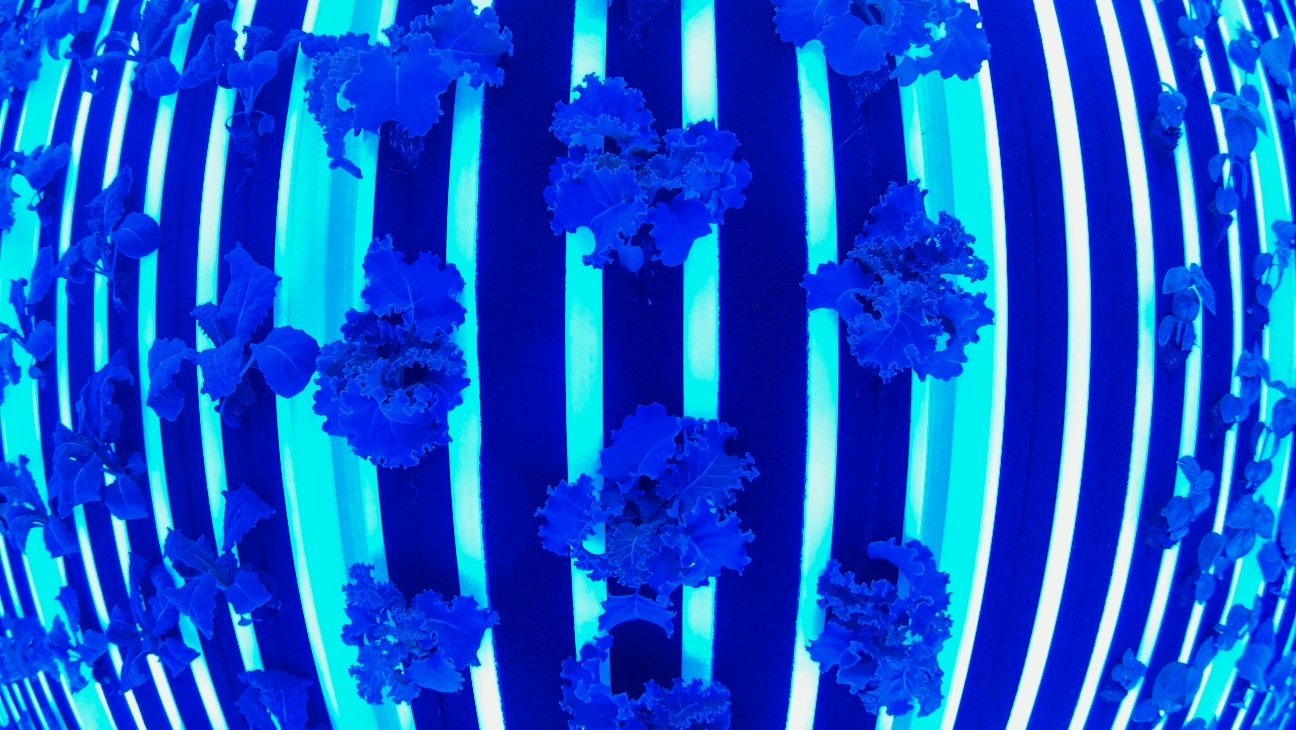

These Plants Get Lit.

Advanced LED technology controls intensity (PPFD) and spectrum, allowing you to customize your grow to enhance, flavor, color, texture, speed and yields

LED Arrays

-

High definition 1080p cameras embedded throughout the LED Walls to monitor plant health and predict possible harvest dates, disease, watering needs, etc)

-

White LEDs fully illuminate the Garden for the operator and act as the flash for the embedded cameras

-

40 high efficiency LED boards provide multiple spectrums and intensity of light to the plant canopy

-

Rack gear belt housing encloses the mechanisms used to move the wall laterally in the Garden

-

Center covers give the user access to the power supplies, camera modules, high and low voltage electrical. Allowing for easy replacement of any and all parts

-

LED boards spaced to create uniform photosynthetic photon flux density

Color, More than Meets the Eye

Specific wavelengths of light are isolated to promote photosynthesis and save energy

Balance of Power

In the cultivation area, the Garden’s LED arrays output an average range of 350 μmol/m2s, meaning plants receive the best quality light at its most efficient point. While more light generally means healthier plants, there are diminishing returns on the rate of photosynthesis after light intensity exceeds a PPFD of approximately 400 μmol/m2s.

The rate of plant growth is directly affected by light intensity (X axis) and the rate of photosynthesis (Y axis). The rate of growth is exponential between 0 and 300 μmol/m2s, but decreases significantly beyond that point because the plant cannot absorb more light even if it is available. Beyond 500 μmol/m2s, light has a minimal effect on the plant’s growth.

PRECISE WATER DELIVERY

Vertical Drip Irrigation

-

Water conditions are monitored and liquid nutrients dispensed into the cultivation tank using peristaltic pumps

-

Mixing with fresh water that is automatically topping off the tank the liquid nutrients create an enriched water solution perfect for the plants

-

Pressure regulated emitters dispense 2gph of the nutrient enriched water to the plants in the panels

-

Water not absorbed by the plants drain through the panel and down into a collection tank

-

The water in the collection tank is automatically pumped back to the cultivation tank where the nutrient levels will be tested and corrected for another cycle to the plant